The debate about the future of work has been heating up lately as robots are replacing more and more jobs. Some people argue that this is the end of humanity, while others believe it’s just the next step in our evolution. So, where does manufacturing stand in all this? Can robots replace human workers in this industry? Let’s take a closer look.

Table of Contents

The History Of Robots In Manufacturing

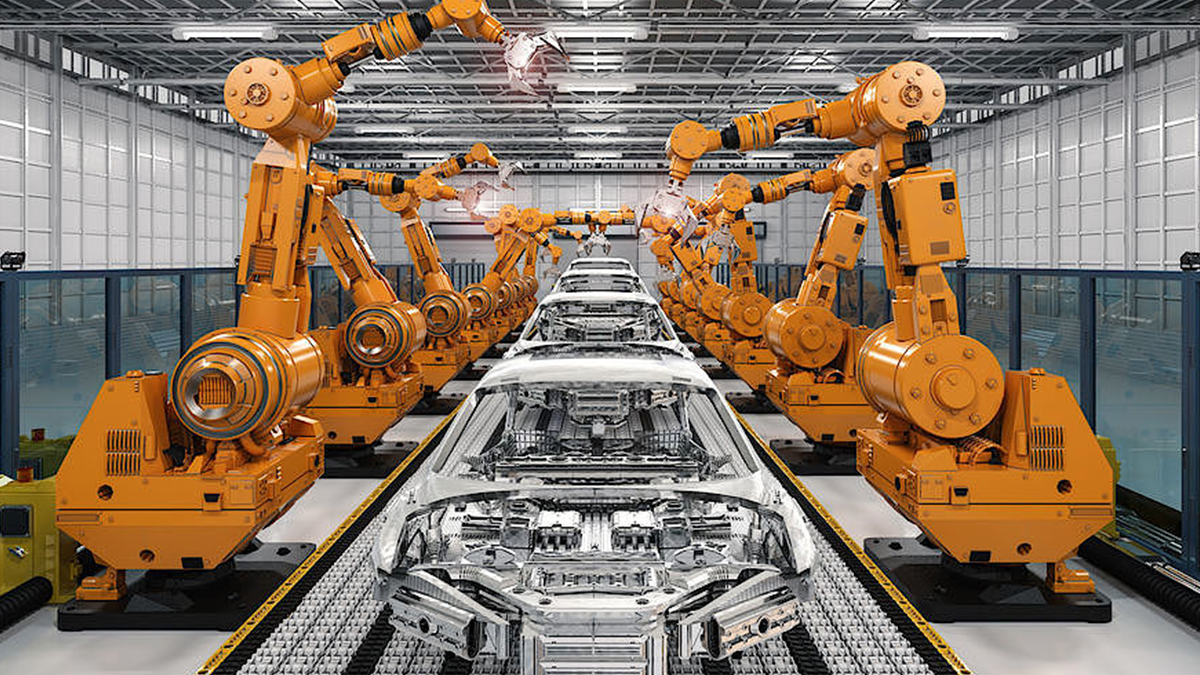

Robots have been used in manufacturing for decades, helping to increase production and reduce costs. Early robots were giant and clunky, crudely mimicking the movements of humans to complete simple tasks. Those early robots significantly advanced human laborers, but they also had limitations.

Fast forward to the present day, and we see a much more advanced generation of manufacturing robots. These modern robots can perform complex tasks with extreme precision and accuracy, paving the way for even greater productivity in the manufacturing world.

Whether we’re talking about automated assembly lines or autonomous vehicles on the factory floor, it is clear that robots are an indispensable part of today’s industrial landscape. And as robotics continues to evolve and advance into the future, we can only expect this trend to continue.

The Benefits Of Using Robots In Manufacturing

There are many reasons why manufacturing companies choose to use robots instead of human workers. First and foremost, robots don’t get tired and can work around the clock if needed. They also don’t require breaks, vacations, or sick days. In other words, they’re much more reliable than human employees.

significant benefit of manufacturing robots is that they can achieve a level of precision and accuracy that is impossible for humans. Robots are equipped with sensors and other sophisticated technology that detect even the slightest irregularities. This attention to detail is essential in manufacturing, where even the slightest mistake can have significant consequences.

In addition, manufacturing robots can work in environments that would be too dangerous for humans, including exposure to toxic chemicals, high temperatures, and loud noise. By using robots in these situations, manufacturing companies can protect their employees from harm and improve working conditions overall.

Finally, it’s important to mention that manufacturing robots can help increase workplace productivity and efficiency. Many experts believe that the widespread use of robots is one of the main reasons manufacturing output has increased significantly in recent years. When robots are used in manufacturing, companies can produce more goods in a shorter period, which helps keep costs down and provides a competitive advantage in the marketplace.

The Disadvantages Of Using Robots In Manufacturing

Despite all the advantages of using robots in manufacturing, some disadvantages exist. One of the most significant issues is the high upfront cost of buying and installing manufacturing robots. In addition, these machines require regular maintenance and repairs, which can add even more to the cost. As a result, small and medium-sized manufacturing companies may not be able to afford to use robots in their operations.

Another potential downside of manufacturing robots is that they can lead to job losses for human workers. It is especially true in developing countries, where manufacturing jobs are often one of the few available employment sources. If robots replace these jobs, it could have a devastating impact on local economies.

Finally, some believe that manufacturing robots are less flexible than human workers. It means they may be unable to handle unexpected situations or make changes on the fly the way humans can.

How Will The Rise Of Robotics Affect Human Workers In The Future?

The rapid advancement of robotics will significantly impact human workers in the manufacturing industry. In many cases, manufacturing jobs will be replaced by robots. It is already happening in developed countries, where manufacturing companies use robots to increase efficiency and reduce costs.

In developing countries, the rise of robotics could lead to even more job losses for human workers. It is because manufacturing companies in these countries may be tempted to replace their human employees with robots to stay competitive. As a result, it’s possible that the already high levels of unemployment in some developing countries could get even worse in the years ahead.

Are Manufacturing Robots Good Or Bad For The Economy?

The truth is there are pros and cons to using robots in manufacturing. On the one hand, these machines offer many benefits in terms of productivity, efficiency, and safety. On the other hand, they can be expensive to buy and maintain, and they may lead to job losses for human workers. Ultimately, the decision of whether or not to use manufacturing robots is up to each company. Some may find that the advantages outweigh the disadvantages, while others prefer to stick with human employees.